Anode material classification and production process

Anode materials are mainly divided into two categories: carbon materials and non-carbon materials. Carbon refers to carbon-based systems, mainly including mesocarbon microspheres, artificial graphite, natural graphite and hard carbon. At present, the most widely used carbon materials are graphite anode materials, among which artificial graphite and natural graphite have large-scale industrial applications. Non-carbon materials mainly include silicon-based materials, tin-based materials, lithium titanate, etc. Among them, silicon-based anode materials are the main research objects of major anode material manufacturers at present, and are one of the new anode materials that are most likely to be applied on a large scale in the future.

Natural graphite process

Natural graphite anode material is natural flake graphite as raw material, after grinding, grading, spheroidization, purification, surface treatment and other processes prepared from the cathode material.

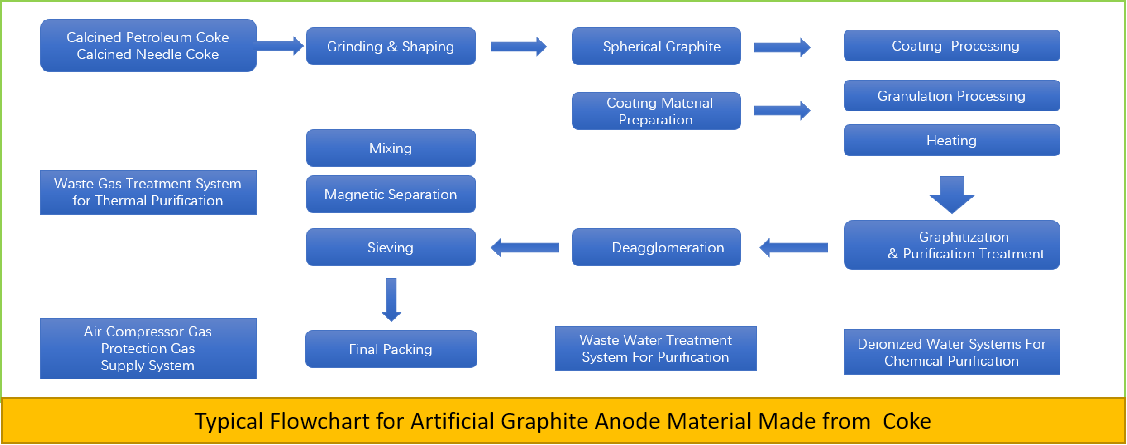

Preparation process of artificial graphite anode material

Artificial graphite manufacturing process can be divided into four steps, more than ten small procedures, granulation and graphitization is the key.The production process of artificial graphite anode material can be divided into four steps: 1) pretreatment 2) granulation 3) graphitization 4) ball milling and screening.Among the four steps, crushing and screening are relatively simple, and granulation and graphitization are the two links that reflect the technical threshold and production level of the anode industry.

Specific to the production process, firstly, one or more of the coke and conductive particles, carbon nanotubes, carbon black, acetylene black are premixed, and then the mixed material and carbon are sintered and coated once, and the prepared particles are graphitized.Graphitized materials and resin materials for secondary coating;Surface treatment with solvent, centrifugation, precipitation and other methods to separate solid particles from the solvent, and then carbonization, 5-20um particles, to obtain a high rate of carbon anode material.In this method, by mixing and fabricating particles, the particles are coated twice to fill the inner shell of the material, so that the internal structure of the material is stable, so that the carbon anode material has the advantages of high rate performance, high pressure compaction, high specific capacity and so on.

(1)preprocessing

Graphite raw material (needle coke or petroleum coke) is mixed with binder for air milling (crushing).According to the different products, the graphite raw materials and adhesive (graphitization) according to different proportions, the mixing ratio is 100 :(5~20), the material through the vacuum feeding machine into the hopper, and then the hopper into the air flow mill for air grinding, grinding 5~10mm diameter of the raw and auxiliary materials to 5-10 microns.After air grinding, cyclone dust collector is used to collect the required particle size materials, the dust collection rate is about 80%, the tail gas is filtered by the filter core filter and discharged, the dust removal efficiency is more than 99%.The material of the filter element is the filter cloth with pores less than 0.2 micron, which can intercept all the dust above 0.2 micron.The fan control system is in negative pressure state.

Difference: pretreatment mill is divided into mechanical mill and jet mill, now the mainstream is jet mill.There are more kinds of adhesives, such as petroleum asphalt, coal asphalt, phenolic resin or epoxy resin.

(2)Granulation/secondary granulation

Granulation is a key step in artificial graphite processing. Granulation is divided into pyrolysis process and ball milling process.

Pyrolysis process: the intermediate material 1 is put into the reaction reactor and electrically heated according to a certain temperature curve in inert gas atmosphere and under a certain pressure. It is stirred at 200-300 for 1-3h and then heated to 400-500 to obtain the material with a particle size of 10-20mm. The material is cooled and discharged, namely the intermediate material 2.Ball mill and sieve division of labor: vacuum feeding, conveying intermediate material 2 to the ball mill for mechanical ball grinding, grinding 10~20mm material into 6~10 micron particle size material, and screening to get intermediate material 3.The material on the screen is transported back to the ball mill by vacuum pipe for ball grinding.

The size, distribution and morphology of graphite particles affect many properties of anode materials.In general, the smaller the particle size, the better the rate performance and cycle life, but the first efficiency and compaction density (affecting the volume energy density and specific capacity) are worse, and vice versa. Reasonable particle size distribution (mixing large particles with small particles, later process) can improve the specific capacity of the negative electrode.The particle morphology also has a great influence on the rate and low temperature performance.

Secondary granulation: small particles have large specific surface area, more channels and shorter paths for lithium ion migration, good rate performance, and large particles have high compaction density and large capacity.How to take into account the advantages of large and small particles, and achieve high capacity and high rate at the same time? The answer is to take secondary granulation.Using the base material such as small grain petroleum coke and needle coke, by adding coating materials and additives, under the condition of high temperature agitation, by controlling the material proportion, temperature rise curve and agitation speed, the small grain base material can be granulated twice, and the product with larger grain size can be obtained.Compared with the product of the same particle size, the secondary granulation can effectively improve the liquid retention performance of the material and reduce the expansion coefficient of the material (there are concave holes between small particles and small particles), shorten the diffusion path of lithium ions, improve the rate performance, but also improve the high and low temperature performance and cycling performance of the material.

Differences: The secondary granulation process has high barriers, many types of coating materials and additives, and is prone to problems such as uneven coating or coating shedding, or poor coating effect, etc. It is an important process for high-end artificial graphite.

(3)graphitization

Graphitization is the orderly transformation of thermodynamically unstable carbon atoms from chaotic layer structure to graphite crystal structure by thermal activation. Therefore, high temperature heat treatment (HTT) is used in the graphitization process to provide energy for atomic rearrangement and structural transformation.In order to improve the graphitization degree of refractory carbon materials, catalysts can also be added.

In order to get better graphitization effect, three aspects need to be done: 1. Master the method of loading resistance materials and materials into the furnace (horizontal loading, vertical loading, dislocation and mixed loading, etc.), and can adjust the distance between materials according to the different performance of resistance materials; 2.2, according to the different capacity and product specifications of the graphitization furnace, different power curve is used to control the rate of rise and fall in the process of graphitization;3, in specific circumstances, in the ingredients to add catalyst, improve the degree of graphitization, that is, "catalytic graphitization".

Differences: Different qualities of artificial graphite have different heating and cooling rates, holding time, catalysts, etc. It is expected that the types of graphitization furnaces used are different, resulting in relatively large differences in performance and cost. Graphitization separated from the front-end and back-end processes, especially the heating and cooling process, is basically programmed, but the graphitization time is long and the equipment investment is large, so more outsourced processing is required, and there is no risk of technology leakage.

Coated carbonization: Coated carbonization uses a graphite-like carbon material as a "core", and coats a layer of uniform amorphous carbon material on its surface to form particles similar to a "core-shell" structure. The precursors of commonly used amorphous carbon materials include low-temperature pyrolysis carbon materials such as phenolic resin, pitch, and citric acid. The interlayer spacing of amorphous carbon materials is larger than that of graphite, which can improve the diffusion performance of lithium ions in it. SEI film, improve the first effect, cycle life, etc.

Differences: Different manufacturers choose different precursors and different heating procedures, so that the thickness and uniformity of the coating layer are also different, so the product cost and performance will also be different.

(4) Screening/doping

The graphitized materials are transported to the ball mill by vacuum, and then undergo physical mixing and ball milling. They are screened with a 270-mesh molecular sieve, and the material under the sieve is inspected, measured, packaged and stored. The material on the sieve is further ball-milled to meet the particle size requirements and then sieved.

Doping modification. The doping modification method is more flexible and the doping elements are diverse. At present, researchers are actively researching this method. Doping non-carbon elements into graphite can change the electronic state of graphite, making it easier to obtain electrons, thereby further increasing the intercalation of lithium ions. For example, the successful doping of phosphorus and boron atoms into the graphite surface and the formation of chemical bonds with them help to form a dense SEI film, which has effectively improved the cycle life and rate performance of graphite. Doping different elements in the graphite material has different optimization effects on its electrochemical performance. Among them, the addition of elements (Si, Sn) that also have the ability to store lithium can significantly improve the specific capacity of graphite anode materials.